Wholesale 65Mn DIN471 Circlips for Hole Retaining Ring non – standard custom

Description:

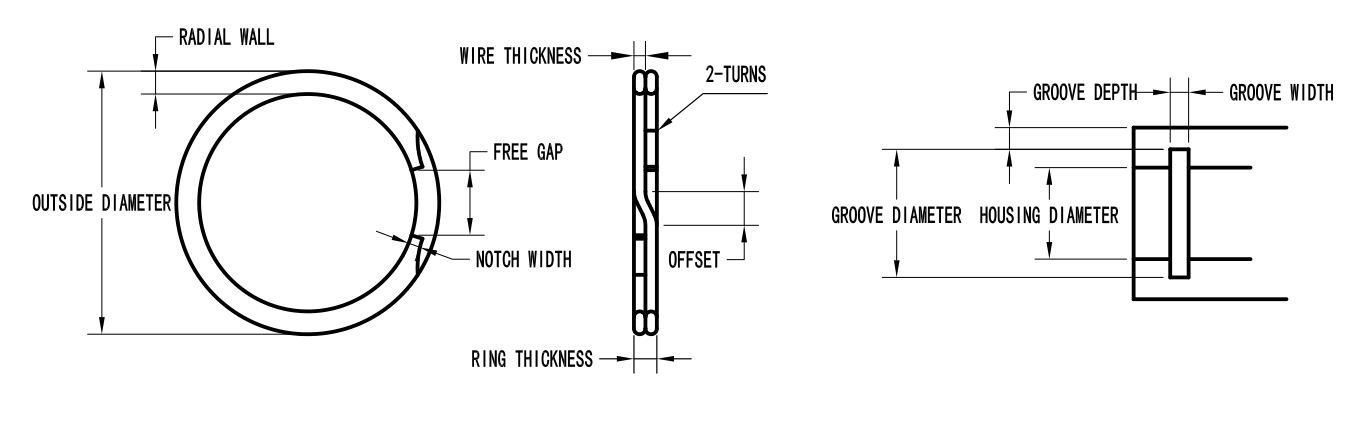

Spiral Retaining Rings have No Ears in your assembly! Spiral Retaining Rings are manufactured by coiling the ring from flat wire. This unique process produces a retaining ring that has no protruding ears or burrs to interfere with your assembly. Because coiling produces a retaining ring with no scrap, the Spiral Retaining Ring can be economically produced in carbon steel, stainless steel, coppers, and many other alloys.

No gap – 360°retaining surface

. No protruding ears interfere with mating components (uniform cross-section)

. Economically produced in stainless steel because the coiling process produces no scrap

. No -Charge on custom designs

. Easy installation and removal

Processing Steps

Design →Drawing→ Flat the wire → CNC Machining → Heat treatment → Surface → Finishing → Quality Inspection → Packing

Finish

Oil Dip,Passivation,blacking, zinc/nickel/chrome/silver/gold plating, powder coated etc

Specification:(Some specifications and sizes can be contacted for details.)

| Part Number | Ring Size | Assembly Size | ||||||

| Specification | Use | Outside Diameter (mm) |

Radial Wall (mm) |

Thickness (mm) |

Turns | Housing Diameter (mm) |

Groove Diameter (mm) |

Groove Width (mm) |

| EK-6 | Internal | 6.35 | 0.43 | 0.38 | 2-Turn | 6 | 6.3 | 0.51 |

| WKM-25 | Internal | 6.86 | 0.51 | 0.38 | 2-Turn | 6.35 | 6.81 | 0.51 |

| EK-7 | Internal | 7.37 | 0.43 | 0.38 | 2-Turn | 7 | 7.32 | 0.51 |

| WKM-31 | Internal | 8.46 | 0.64 | 0.38 | 2-Turn | 7.92 | 8.38 | 0.51 |

| EK-8 | Internal | 8.51 | 0.61 | 0.38 | 2-Turn | 8 | 8.43 | 0.51 |

| EK-9 | Internal | 9.6 | 0.74 | 0.64 | 2-Turn | 9 | 9.5 | 0.74 |

| WKM-37 | Internal | 10.16 | 0.76 | 0.64 | 2-Turn | 9.53 | 10.08 | 0.74 |

| EK-10 | Internal | 10.62 | 0.74 | 0.64 | 2-Turn | 10 | 10.52 | 0.74 |

| EK-11 | Internal | 11.79 | 0.86 | 0.64 | 2-Turn | 11 | 11.71 | 0.74 |

| WKM-43 | Internal | 11.79 | 0.89 | 0.64 | 2-Turn | 11.1 | 11.71 | 0.74 |

| EK-12 | Internal | 12.89 | 1.12 | 0.6 | 2-Turn | 12 | 12.7 | 0.7 |

| WKT-50 | Internal | 13.44 | 1.14 | 0.89 | 2-Turn | 12.7 | 13.31 | 0.99 |

| WK-50 | Internal | 13.51 | 1.14 | 0.64 | 2-Turn | 12.7 | 13.36 | 0.76 |

| WKM-50 | Internal | 13.67 | 1.14 | 0.89 | 2-Turn | 12.7 | 13.46 | 0.99 |

| DNK-13 | Internal | 13.72 | 1.4 | 0.99 | 2-Turn | 13 | 13.6 | 1.1 |

| WKT-51 | Internal | 13.74 | 1.14 | 0.89 | 2-Turn | 13 | 13.61 | 0.99 |

| WK-51 | Internal | 13.82 | 1.14 | 0.64 | 2-Turn | 13 | 13.67 | 0.76 |

| EK-13 | Internal | 13.95 | 1.12 | 0.89 | 2-Turn | 13 | 13.75 | 1 |

| WKM-51 | Internal | 13.97 | 1.14 | 0.89 | 2-Turn | 13 | 13.77 | 0.99 |

| WK-53 | Internal | 14.33 | 1.14 | 0.64 | 2-Turn | 13.49 | 14.15 | 0.76 |

| DNK-14 | Internal | 14.75 | 1.4 | 0.99 | 2-Turn | 14 | 14.6 | 1.1 |

| EK-14 | Internal | 15.07 | 1.37 | 0.89 | 2-Turn | 14 | 14.85 | 1 |

| WK-56 | Internal | 15.09 | 1.14 | 0.64 | 2-Turn | 14.27 | 14.94 | 0.76 |

| WKT-56 | Internal | 15.16 | 1.14 | 0.89 | 2-Turn | 14.27 | 15.04 | 0.99 |

| WKM-56 | Internal | 15.37 | 1.4 | 0.89 | 2-Turn | 14.27 | 15.14 | 0.99 |

| DNK-15 | Internal | 15.85 | 1.4 | 0.99 | 2-Turn | 15 | 15.7 | 1.1 |

| WK-59 | Internal | 15.9 | 1.14 | 0.64 | 2-Turn | 15.09 | 15.72 | 0.76 |

| EK-15 | Internal | 16.14 | 1.37 | 0.89 | 2-Turn | 15 | 15.9 | 1 |

| WK-62 | Internal | 16.71 | 1.14 | 0.64 | 2-Turn | 15.88 | 16.54 | 0.76 |

| WKT-62 | Internal | 16.89 | 1.14 | 0.89 | 2-Turn | 15.88 | 16.74 | 0.99 |

| DNK-16 | Internal | 16.97 | 1.65 | 0.99 | 2-Turn | 16 | 16.8 | 1.1 |

| EK-16 | Internal | 17.15 | 1.37 | 0.89 | 2-Turn | 16 | 16.95 | 1 |

| WKM-62 | Internal | 17.15 | 1.4 | 0.89 | 2-Turn | 15.88 | 16.89 | 0.99 |

| WK-65 | Internal | 17.5 | 1.14 | 0.64 | 2-Turn | 16.66 | 17.32 | 0.76 |

| DNK-17 | Internal | 17.98 | 1.65 | 0.99 | 2-Turn | 17 | 17.8 | 1.1 |

| WK-68 | Internal | 18.29 | 1.14 | 0.64 | 2-Turn | 17.45 | 18.11 | 0.76 |

| EK-17 | Internal | 18.32 | 1.63 | 0.89 | 2-Turn | 17 | 18.05 | 1 |

| WKT-68 | Internal | 18.54 | 1.4 | 0.89 | 2-Turn | 17.48 | 18.39 | 0.99 |

| WKM-68 | Internal | 18.87 | 1.65 | 0.89 | 2-Turn | 17.48 | 18.59 | 0.99 |

| WK-71 | Internal | 19.08 | 1.14 | 0.64 | 2-Turn | 18.24 | 18.9 | 0.76 |