Nested wave springs Wave pad manufacturers for motor

Description:

Nested Wave Springs are pre-stacked in parallel from one continuous filament of flat wire. The need to stack individual springs for higher loads is no longer necessary. Nested springs result in a spring rate that increases proportionally to the number of turns. They can exert tremendous forces, yet maintain the precision of a circular-grain wave spring. In many applications, Nested Wave Springs replace Belleville Springs, particularly in cases where a high but accurate force is needed.

Specification:

|

Material |

OIL TEMPERED(SAE1070-1090), HARD DRAWN SAE 1060 – 1075, stainless steel 304,316,631,17-7PH(SUS), beryllium copper, phosphor copper,65Mn, A-286 , Inconel Alloy X-750 ,X-718 ,Elgiloy ,MONEL K-500, MONEL 400 etc |

|

Processing Steps |

Design →Drawing→ Flat the wire → CNC Machining → Heat treatment → Surface → Finishing → Quality Inspection → Packing |

|

Finish |

Oil Dip,Passivation,blacking, zinc/nickel/chrome/silver/gold plating, powder coated etc |

|

Applications |

For aerospace, automotive, medical, off-highway, oil & gas , Wind power ,Consumer Industrial |

|

Primary Competitive Advantage |

•Over 3000 types Wave springs and Spiral rings standard parts in stock •Prompt Delivery Quality Approvals•Service Sample Available•We have over 10 years of professional experience as a manufacturer of Wave springs , Spiral Retaining Rings , Constant Section Retaining Ring , Laminar Seal Rings |

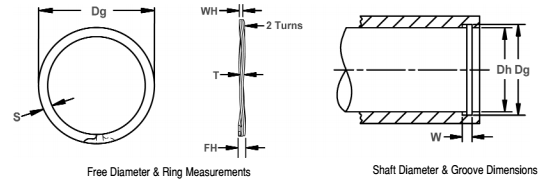

Wave spring measurements: